CameraBloks

CameraBloks

People are talking about modular phones and of course that makes us think about modular cameras. Phil Rhodes has some lucid ideas about this, and then there's the Apertus Axiom, which we've covered before.

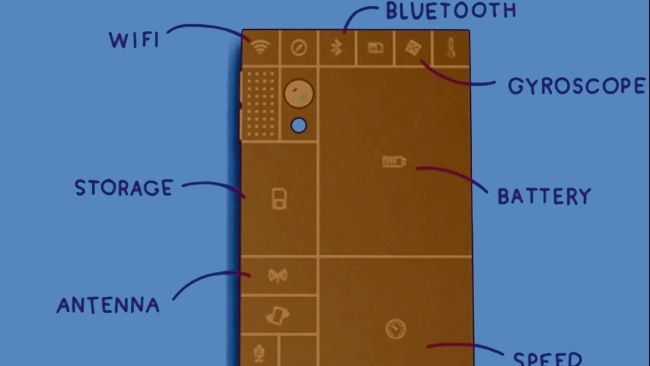

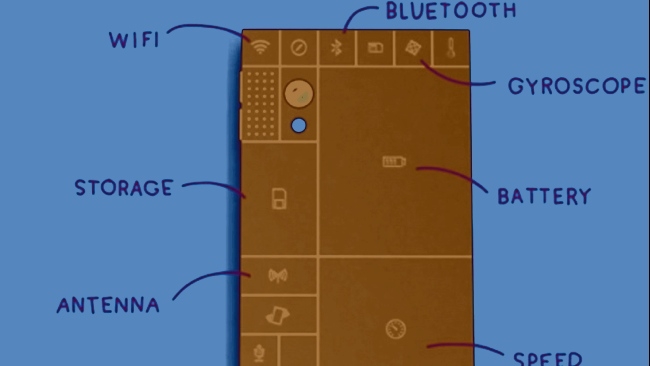

The idea behind PhoneBloks is based on the realisation that cellphones, or more specifically the modern smartphones at which the concept seems to be addressed, tend to include at least several of a fairly standard range of subsystems: principally display, processing, power and radio communications, but also things like storage, a camera, other communications options, and so on.

Often, when a phone fails or becomes obsolete, only one or two of those subsystems are the cause of the problem. However, with modern manufacturing techniques highly reliant on an enormous degree of integration, sometimes putting a variety of functions not only on one circuit board but within one piece of silicon, it's generally impossible to upgrade or fit replacement parts to a cellphone piecemeal in the same way we might update a desktop computer. This means that only slightly outdated or only slightly defective technology is often thrown out, and quite apart from the environmental issue, technical people will be familiar with the feeling that it's offensive to throw out good, working technology, especially of the level of complexity of a modern smartphone, on the basis of a relatively trivial failure.

Hakken's Concept

Hakken's idea is conceptually simple: to make these subsystems individually upgradeable and replaceable. The implementation he suggests is to provide a flat rectangular substrate, perforated with holes providing both power and data connectivity, with a latching mechanism to allow modules to be plugged in, clamped in place, powered up and used. The result resembles nothing more than a collection of lego pieces on a flat baseboard, but the specific physical implementation is not necessarily what's of interest here. Hakken wants this system standardised so that anyone can make components for it – in fact, he recently turned down a job at Motorola, who seem to be interested in his ideas, on the basis that he wanted to avoid tying those ideas to any particular company.

My contention, as you'll no doubt have realised by now, is that an approach along these lines could work for camera equipment just as well.

Overlooking both technical and political concerns for a moment, there are several reasons why this might be desirable, quite apart from Hakken's concerns over e-waste. The first and perhaps most persuasive is that the modular cameras approach is, to all practical purposes, already being used by people accessorising domestic or prosumer cameras into configurations more suitable for various specific roles. Most readers will be familiar with the idea of strapping a DSLR to a set of rods, slapping a recorder on the back and hanging a viewfinder off the side. I make no representation as to whether this rather haphazard approach is an attractive idea that anyone actually wants to pursue, or whether people who do this do it because it's a good way of making a cheap camera more usable. I think it's probably a bit of both, but either way it is certainly being done and it could be done better with components designed more specifically for the situation.

PhoneBlok Benefits

Often there can be reliability and usability concerns over the fragility of connectors and cabling that wouldn't exist in a more integrated device, but even as it is, this approach does actually realise some of the benefits that Hakken anticipates for PhoneBloks. Parts are held together with standardised interfaces: a lens mount, a video transport standard such as HDMI, a battery mount, and the ubiquitous 15mm rods. Parts can be upgraded or replaced individually. And crucially, for the sake of creating a generalised ecosystem, most of the standards that allow these parts to be assembled can be implemented by any competent developer, and the market for both mechanical and electronic components is thriving.

Challenges

There are, naturally, challenges, and it's a mistake to assume that any such system might emerge overnight. Even defining the level of modularity might prove difficult. For instance, there's a legitimate argument over whether any such system would provide a “camera” module, with sensor and electronics integrated, or separate “sensor” and “image processing” modules. The latter solution is attractive from a flexibility standpoint – greater granularity always would be – and would allow, for instance, for a simpler set of processing electronics to be applied to an ENG camera than might be desirable on a device intended to shoot movies, or for raw modules supporting single-chip Bayer cameras with only very basic processing capabilities to drive a viewfinder. This might allow for lower power consumption in certain cameras, although there is a legitimate concern that the wide variability of sensors (including fundamental differences such as single or 3-chip designs and various colour mask patterns) might make this impractical, or at least not worthwhile.

Subdivision would also, given the necessary practicalities of industrial design and mechanical assembly, add to weight, bulk, cost and reliability concerns. Any modular subdivision at all will tend to make a device bigger and heavier, and possibly more costly, than a fully integrated version of the same thing. Dockable video camera-recorder combinations, which were popular from the 80s up to the mid-2000s and even to date, suffer to some extent from these problems. This is one of the principal practical concerns with this whole concept, and people have warned that David Hakken's ideas for cellphones risk the necessity of making them physically bulkier than some current smartphone customers would tolerate.

Minimising the Issue

To minimise this problem, it would be necessary to design a mechanical architecture for a modular camera that did not require individual modules, which might contain only a single circuit board, to be very much thicker than the circuit board itself. For instance, a modular camera of similar function and form factor to a DSLR or a Blackmagic Cinema Camera might require sensor, processing, codec, power, recorder and display for a total of six modules, most of which would need to be very thin to approximate the general layout of a similar device. Most of these would comprise a single PCB, perhaps with a flash slot or TFT panel. It would not seem unreasonable to target a minimum module thickness in the single digits of millimetres given extant technology, assuming some sort of low-profile dovetail mounting arrangement, although there will always be devices – such as the very smallest DSLRs and GoPro style specialist cameras – for which a modular approach might never be practical.

Feasibility

The technical feasibility of a modular camera system also relies on the implementation standardised communications between parts. The need to transfer high-speed image data between components implies some sort of data bus, and this needs to handle not only uncompressed sensor data or processed camera data, but also needs to be sophisticated enough to correctly address streams representing untouched production images and pictures with test-and-measurement data overlaid, for display in a viewfinder, as well as audio data, power, and other information. Codec modules might also output various types of compressed data, which would need to be differentiated and handled appropriately so they can be recorded. A secondary, low-speed control and status bus, such as I2C or SPI, would seem reasonable to avoid non-imaging components such as power management or control panels needing to implement the high speed bus, in much the same way that current computer systems use SMbus to manage cooling devices, time, lid switches, and so on.

Perhaps the most trying goal would be to provide both backward and forward compatibility, such that a complete system could be upgraded to a more capable sensor which would require a more capable codec and recorder, without obsoleting, for instance, viewfinding and monitoring modules which might continue to work with images provided by a downsampling module. This could be done, given sufficiently careful thought about providing pass-through options for modules that might not be able to directly handle things developed after their release.

There are a number of ways in which this might be achieved. An optical bus suggests itself, given the ability of a single link to maintain extremely high bandwidth, and because of the relative simplicity of allowing a pass-through option which, we might hope, would remain forward compatible for a reasonable period. The physical compactness of a single-fibre optical connection might allow for several fully independent buses, allowing the most capable components of a system to communicate at maximum rate, while reserving space for older, slower things to talk over another link. A more conventional approach, avoiding the comparatively exotic hardware of optical communications, would be simply to provide a multi-serial electrical bus on the model of PCI Express or HyperTransport, the most capable of which (being HyperTransport 3.1, a 3.2GHz 32-pair link) could transport over a thousand fifty-megabyte 16-bit 4K RGB frames per second, providing adequate capability for anything other than the most exotic camera systems.

Module Engineering

Either solution would require reasonable engineering in modules to provide accurate mating, integrity of high frequency signals, and adequate physical robustness. HyperTransport is designed to run around the mainboard of a computer workstation, although PCI Express has proven ability to tolerate passage through connectors – Blackmagic's Multibridge series uses DVI connectors and cabling to route the PCIe bus from workstation to external device. A camera might not literally implement HyperTransport or PCIe, although experience with these and similar buses indicates that these are not insurmountable technical problems.

The other, perhaps more difficult problem with modular technology concepts is the willingness of commercial entities to become involved with new standards. On one hand, everyone likes standards; this is why we have so very many wildly different ones (or better yet, not quite identical ones). On the other, there is considerable commercial imperative towards vendor lock-in and proprietary technology.

Promoting Proprietary Technology

Objectively, I don't think a modular camera concept necessarily costs anyone the ability to promote proprietary tech, in as much as a high grade camera module remains a high grade camera module thatcan be promoted and sold as such, regardless of whose recorder is in use (and this is already happening given the popularity of standalone recorders). Beyond that, while there might be fears that sales would be eroded given the new ability to repurpose and refresh old gear, there is the potential to create an entirely new market, much as the modularity of computer workstations has done. Ordinarily, a private owner or rental facility is forced to choose a particular type of camera to buy, and this market should persist, with preconfigured sets of modules for common tasks. But there are additional opportunities to sell those customers, for instance, a second sensor module for each

camera, such it could be used for, say, ENG one day and music videos the next. That's an upsell on the previous situation, and a new opportunity: a user might be unlikely to buy two completely separate cameras, but someone might choose to buy a much more affordable module for an existing one.

But the main factor mitigating concerns over loss of market is that this has happened before, and not only in the rather approximate circumstances of a DSLR rig. It's not as commonly done as once it was, but it's still just about possible to see people shooting DVCAM for broadcast news on cameras comprising a DSR-1 video tape recorder docked to a DXC-D35 camera. But more than that, you can also dock the DSR-1 recorder, a Sony product, to an Ikegami HL-45W camera head, and end up with something that's functionally equivalent (and no, I do not intend to comment on the relative merits of Sony and Ikegami, which is at best an ecumenical matter).

More than that, we have for years enjoyed the ability to select a battery system from one of several manufacturers, a lens from another, and even a quick-release tripod plate which is widely compatible. None of these represent anything like the electronic sophistication required of a modular camera system, but they do represent the willingness of companies in this market to work to common standards.

Modularity in Workstations

What certainly does represent a similar level of technological sophistication in the implementation of standards is the modern computer workstation. The performance of certain parts of a modern PC is at or beyond the level required of a modular camera, and the way in which parts interoperate is considerably more complicated. It is a triumph of standardisation, one of the most significant examples in modern technology, and it is done regardless of the fact that many of the companies involved are in direct competition. AMD, for instance, now own what was the graphics processor developer ATI, but it is entirely possible to buy a graphics board from their bitter rivals Nvidia and plug it into the same motherboard as an AMD processor where they will interoperate happily and with very high performance. The competitive relationship between the two is an example of a free market working properly, and has provided much of the enormous advance in realtime graphics and

GPU computing seen in the last two decades. Regardless, these competitors implement advanced technical standards and interoperate fully.

So, there is no real reason why this couldn't work. It's technically and commercially feasible as amply demonstrated by comparable technologies and desirable as a replacement for approaches that do much the same thing.

Enough Variations for Valuable Combinations?

The only problem is whether there's actually enough variation in requirements to make it worthwhile. There are, very broadly, only a few categories of camera in the world:

− Cameras for ENG or documentary, with shoulder mount and handgrip lens;

− Cameras for feature film or single-camera drama;

− Studio pedestal cameras;

− Small, highly integrated handycams and prosumer cameras;

− DSLRs and similarly-laid-out products such as the Blackmagic Cinema Camera;

It's easy to argue over those definitions, but even if we managed to double the length of that list – which we might struggle to do – there is a legitimate question over whether any greater degree of granularity in the configuration of a camera is necessary.

For the sake of comparison, consider that home-PC enthusiasts, who often build computers around the exigencies of video games, might not actually upgrade a processor separately from the system mainboard or RAM; significant CPU upgrades very often require a new motherboard and memory anyway. Even so, that still represents not replacing the case, the power supply, graphics card, hard disks, monitor, mouse, keyboard, and other storage devices, and with sufficient attention to forward compatibility, I don't think this model is entirely discouraging.

What I certainly do think is that the approach of cobbling together camera rigs out of modified and accessorised stills cameras, while it's provided an absolutely massive boost in capability to the low end, is not something any of us want to see become the norm. If we're going to end up throwing camera rigs together out of piece parts, let's at least consider having piece parts that are designed to be used in that way.

RedShark's article on the Apertus Axiom modular - and open source - camera

Tags: Technology

Comments