Networks are becoming increasingly important, and not only in IT environments, but also production and post production. But they are only as good as the cables that connect them.

Sommer Cable is one of the biggest players in the manufacturing and distribution of copper and fibre optics based cables. It sells, directly as well as in its OEM capacity, cables and equipment for the broadcast and film production industries. If there’s one company that has the knowledge of CAT cabling and its challenges, it’s bound to be Sommer Cable. I personally don’t have their network cables, but have purchased their Carbokab and quad core microphone cables in the past, and know from personal experience what quality you can expect from their top-end products but also how well their product managers are informed about the technical aspects and the market.

With that in mind, below is a distilled conversation with Key Account & Product Manager Peter Rieck from Sommer Cable, who outlined the advantages and problems of CAT (copper) cables, and also offered some insights on the subject of CAT versus fibre optics.

Copper versus optical fibre

To me and you, the benefits of optical fibre are obvious. There’s practically no limit as far as bandwidth is concerned, the segment length is unlimited and there are no problems with isolation. To Rieck, fibre has less expected downsides. Cable ends can only be terminated with great effort, there is no PoE option and you’ll always need active signal converters or switches, because very few terminal devices are equipped with onboard fibre optical connections.

These disadvantages mirror the strong points of copper cabling. PoE is becoming the standard for supplying terminal equipment; nearly all stationary end devices feature an appropriate connection. The termination requires little effort and no special tools. And owing to the Ea (CAT6a) and class I (CAT8.1) cables, bandwidth is future proof. Whatever drawbacks exist, they are all manageable. The segment length provisions are stricter, the minimum bending radii — larger than with optical fibre — must be adhered to during installation, and potential equalisation needs to be observed, but that’s it.

From the point of view of the cable provider/installer, the advantages clearly speak in favour of CAT cables. For the end user, the high bandwidth made possible by CAT6a and CAT8.1 standards are one thing, the far bigger number of applications are another. Especially PoE is really important as this can only be handled by copper lines.

Copper, however, has less of a sustainability label than optical fibre. That, though, can be alleviated to a considerable level by selecting high-quality products that are intrinsically more durable. Installing, routing and treating them correctly will add to the longevity of a cable, its connectors and the mechanical stress on the interface.

Yet, in terms of sustainability, it’s useful to note that especially with PoE applications, a CAT line can age faster than one might think.

PoE and protocol

That’s because PoE over CAT is not quite as trivial as people assume and not only in terms of sustainability. Power over Ethernet is not a standard. In fact, there are numerous proprietary “standards“, each with their own challenges as far as the terminal devices and the infrastructure, i.e. the wiring, are concerned. Also, quite a bit of power is lost in the form of heat.

It all depends on the field of application, though, as Rieck points out. In pure ethernet environments, there are standardised PoE protocols where you can be sure everything will be compatible and there’s no risk of damaging the equipment. That’s not necessarily the case with alternative application fields such as HDBaseT, where sometimes proprietary solutions are used. In these fields, it cannot be taken for granted that you can connect devices without further consideration.

And even pure ethernet PoE has the disadvantage of generating up to 30% of heat, especially with larger cable bundles, because of its low efficiency. In an S/UTP or even U/UTP environment, this is a problem as an internal temperature rise of 10°C will halve the cable’s service life.

Consequently, plug-in connections must be equipped with optimised connectors, all the more so because there’s a large risk of flashovers that may occur when unplugging. In non-optimised connectors, this will erode the gold plating after a few mating cycles, quickly making connections unreliable. The problem is confounded by high data bandwidths, so there’s no getting around connectors with a built-in compensation. Notably crosstalk between pairs 3/6 and 4/5 is a big problem.

Fortunately, independent test institutes like the GHMT in Europe issue certificates to give integrators some guidance.

CAT isn’t to be taken for granted, neither is cable length

A rule of thumb with network cabling is that the category always relates only to the individual component; i.e. the connector or the cable. Usually one talks about CAT5, CAT6, CAT7 or even CAT8 networks, but strictly speaking this is not correct. The system and the network are always subdivided into application classes which run in parallel to the component category. However, a network may also contain components from different categories. Hence, the network class is always a general overview.

The industry’s to blame as well. The use of CAT5, CAT6 or CAT7 for designating a network is not correct, either. One should really call it a class D, E or F network.

Also, when talking about the subject of cable lengths there are some misunderstandings. The classes stipulate maximum link lengths. This means that when building a network as an integrator to a class I target, for example, I need to know that the link length must not exceed 30m. But when I have to comply with class EA using the same network cable, I can go all the way up to 90m. Category 7A and 8 cables come with a large AWG22 cross-section anyway, so it’s non-critical.

However, an old class D network with AWG24 cables that needs to be converted to PoE is a whole different matter. The combination of presumably unshielded twisted pairs and a low cross-section makes this quite challenging. Here it is advised to stay with considerably lower link lengths.

Audio

Finally, in the fixed installation sector, people sometimes use CAT7 or CAT7 duplex cables for transmitting analogue audio. Here, however, the shields of the four audio channels that can be transmitted via a CAT cable are combined and the cross-section is larger.

With a CAT7 or CAT7a installation cable you’ll need something like AWG 23 or even AWG 22. Usually, a modulation cable for analogue or digital audio applications has a smaller cross-section. Except for the meshed shields, which are only connected via a RJ45 housing, there are no significant drawbacks. These cables have been designed for much higher frequencies and boast outstanding crosstalk values.

What’s trending

Unified networks are becoming a trend. So far sound, light, video, stage engineering, etc, have been sitting on their own network. But it makes sense to provide one single network for all to share, provided the installer closely follows up on how transmission standards will develop.

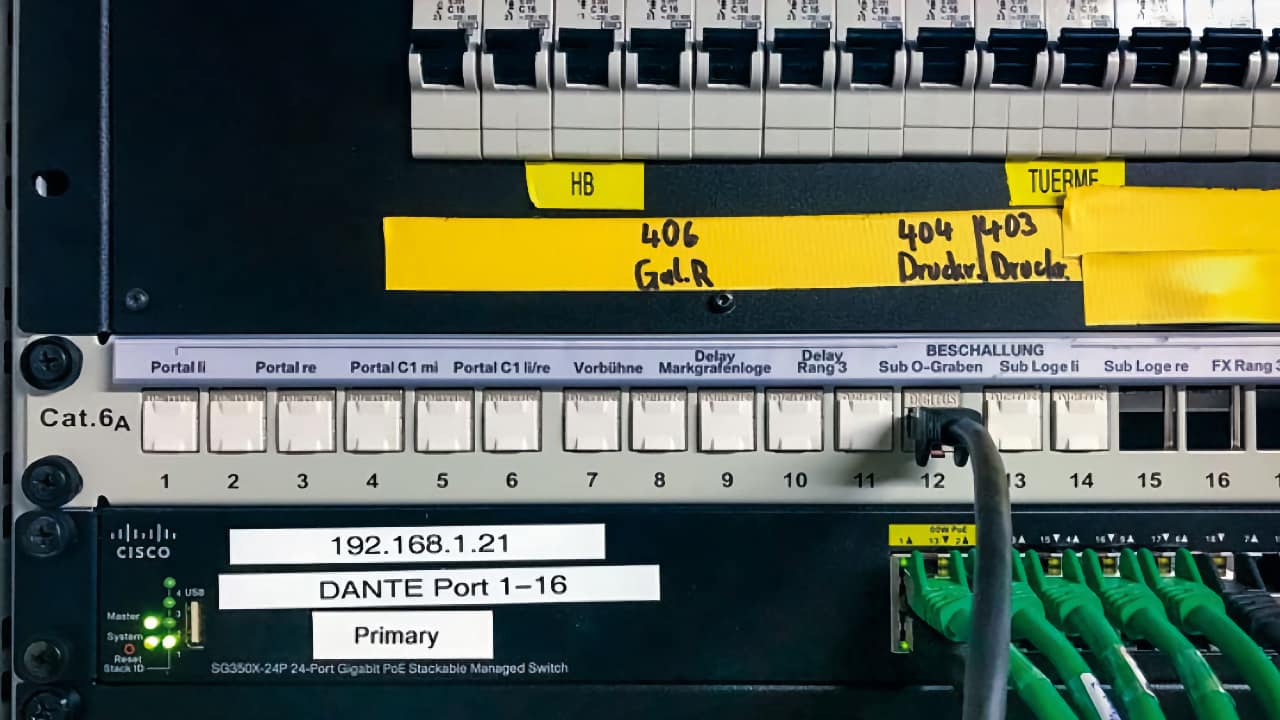

Things are already clearly moving towards having everything on native ethernet. That allows the use of standardised cables, lines, patch panels, etc. CAT6a (class Ea) and CAT8.1 (class I) standards ensure that solutions are failsafe because of the available bandwidth. This means you only need to deal with signal management since the infrastructure is the same for all.

Tags: Production

Comments