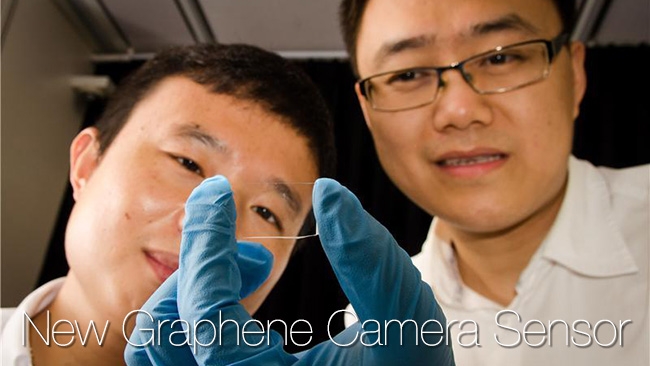

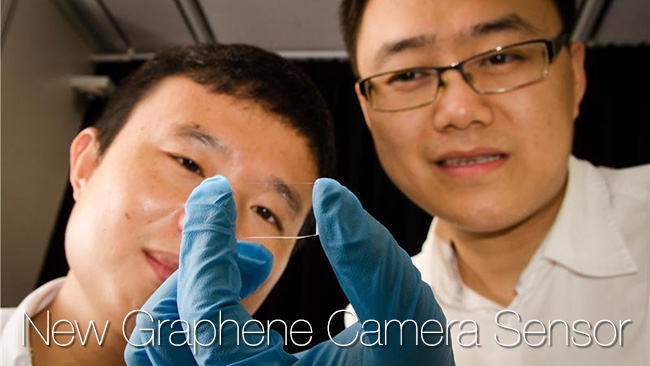

The new Graphene Sensor

The new Graphene Sensor

Scientists at Nanyang Technological University in Singapore have developed a new sensor technology based on Graphene, which is 1000 times more light sensitive than existing CMOS or CCD sensors

We've already heard about Graphene being used as the diaphragm in a pair of Headphones, but now it seems this amazing material can also be used in a new type of Camera Sensor. In laboratory testing the Graphene sensor was shown to be approximately 1000 times more sensitive to light than CMOS or CCD sensors which are currently in use, whilst at the same time using 10 times less power.

Graphene is a form of Carbon with a unique structure, the Carbon atoms are connected in flat hexagons to create a structure like chicken wire, but only a single atom thick. It has very unusual electrical properties, as well as amazing flexibility and durability, and is being tested by Scientists in Laboratories all over the world to find new practical applications.

Highly sensitive

The inventor of the new Graphene Sensor, Assistant Professor Wang Qijie, from NTU's School of Electrical & Electronic Engineering, said it is believed to be the first time that a broad-spectrum, highly photosensitive sensor has been developed using pure Graphene.

"We have shown that it is now possible to create cheap, sensitive and flexible photo sensors from Graphene alone. We expect our innovation will have great impact not only on the consumer imaging industry, but also in satellite imaging and communication industries, as well as the mid-infrared applications,"

The structure of the new sensor is created by Nano-engineering the surface of a Graphene sheet to create "traps" for photons of light, which give it its incredible sensitivity. The process has been designed to be compatible with existing manufacturing techniques and so the cost is expected to be roughly five time less than current sensors.

"While designing this sensor, we have kept current manufacturing practices in mind. This means the industry can in principle continue producing camera sensors using the CMOS (complementary metal-oxide-semiconductor) process, which is the prevailing technology used by the majority of factories in the electronics industry. Therefore manufacturers can easily replace the current base material of photo sensors with our new nano-structured Graphene material."

Although it will take time to develop the sensors into a commercial product it does mean we can expect future cameras to have light sensitivity approaching that of the Human Eye, together with lower power consumption and hence longer battery life.

Tags: Technology

Comments