One of the things new technology makes easier is designing new technology. That’s good news for everyone, but it’s particularly useful in niche industries like film and TV where there’s a constant need for high-tech devices in numbers that don’t really support the large volumes of normal (or at least, historically normal) manufacturing practices.

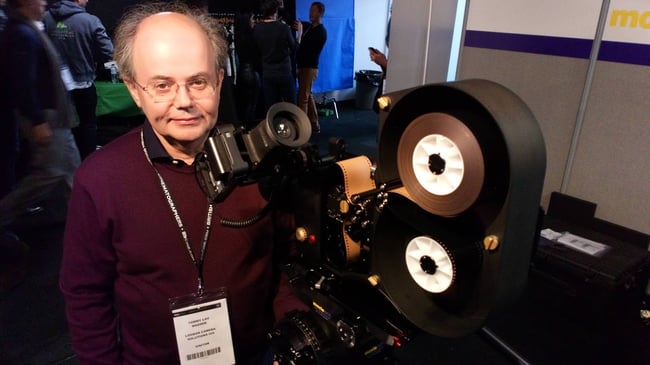

Twenty years ago, cameras like the Logmar Magellan 65mm camera probably wouldn’t have existed. It is, in the estimations of designer Tommy Madsen, mainly the result of having produced drawings on a computer and sent them away to jobbing machine shops for manufacturing. That’s the sort of information that’s only released by companies that are entirely at peace with the fact that they’re doing things that way, but most of them do it. The approach makes things cheaper and easier, no matter how many units they're making, because not every company now has to maintain a huge machine shop. It makes things like the Magellan possible outside the confines of a large organisation in a way they wouldn’t have been previously.

Tech builds tech

Things are even easier with electronics. A lot of people will be aware of things like Arduino, which is essentially an AVR-series micro-controller with training wheels. The AVR was developed by Atmel but is now owned by the confusingly named company Microchip, but the Arduino board and software libraries are a third-party effort. It’s important, not particularly because of the training wheels. It’s quite possible (and often a good idea) to write native AVR code on an Arduino. What’s important is that it’s packaged up as a little USB-connected board with friendly software that doesn’t force people to become expert computer systems administrators in order to even start working. Arduino boards are so cheap that they’re often used to solve tricky issues with basic industrial automation – things like controlling tape decks or camera run-stop features. Whole projects have been built around the Arduino core; various things suggest that the CineRangeFinder ultrasonic focus assist deviceultrasonic focus assist device owes something to Arduino.

Logmar Magellan 65mm camera

It doesn’t work for everything. Certain technologies – precision things, involving ongoing adjustments and skilled work – haven’t really become that much simpler with more modern technological support. One project that springs to mind is the resurrection of the Ferrania film manufacturing plant in the eponymous Italian town, something that was being talked about way back in 2013 with promises of an ISO 100 reversal film stock to be available in 35mm, something which would be a welcome addition to the market.

Ferrania's history includes a variety of interesting stocks

Now, we really shouldn’t be too critical – the people at Ferrania are trying to resurrect a gigantically complex industrial process on a shoestring budget and they’ve faced serious problems with the usability of the buildings in the face of asbestos remediation and the installation of a major new plant, but that 35mm reversal stock hasn’t happened yet. Much has been achieved and the Ferrania P30 panchromatic black and white film has been met with favourable reviews, but ultimately the precision formulation and coating process required to make colour film stocks is not a problem that’s easily solved with a computer. None of this is any comment – either way – on the sterling work done by the people at Ferrania, or the practicality of launching a photochemical film manufacturer in the late 2010s. It’s just an example of something that’s far less amenable to being solved by software or electronics.

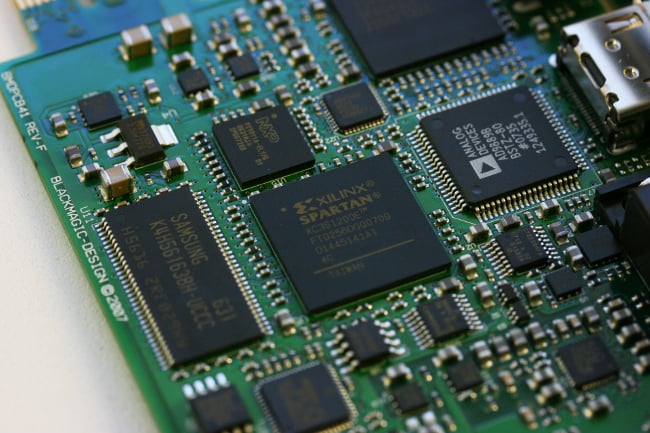

Blackmagic has made several very capable cameras based largely on programmable logic

Camera manufacturers in general, by which we inevitably mean manufacturers of digital cameras, have done better out of new development tools. A modern camera is fundamentally a back-end for a sensor with some colour processing in embedded electronics. While the sensor remains a difficult, cutting-edge piece of technology – and there can be a lot of opinion-based tweaking of colour performance – the electronics are made a lot easier by programmable logic. This technology allows microcircuitry to be expressed as code to be run on a chunk of silicon that can become many things, depending on the programmer’s needs, and avoids the huge expenses of manufacturing custom microchips.

It’s core to the offerings of many current manufacturers of all kinds of film and TV electronics, but it’s also available to more or less anyone – development boards for FPGAs start at a few tens of most units of currency and go all the way up to monsters capable of applying LUTs to video footage on the fly. It takes knowledge – it always did – but it no longer takes the financial resources of an IBM to get started.

SmallHD 1703

Several of the small and medium-sized companies which serve the specific needs of the film and TV industry owe quite a lot to all of this. Organisations the size of Sony or Panasonic benefit too, but economic factors often keep the big players out of the most specialist fields. Let’s end, then, on a tale of Doritos, American football and on-camera monitors as publicised by the people at SmallHD. It’s a tale of combining technologies and commissioning manufacturing that launched the people involved on a course that would eventually lead to becoming part of Vitec and a well-respected manufacturer of displays and, like Logmar’s Magellan camera, it is not something that would have been nearly so easy to do in decades past.

Tags: Technology

Comments